GI Grating

Price 102.0 INR/ Kilograms

MOQ : 1 Kilograms

GI Grating Specification

- Open Style

- Fixed

- Dimension (L*W*H)

- Customized (commonly 1000mm x 600mm x 25mm or as per requirement)

- Life Span

- 10-25 Years (Depends on usage and environment)

- Connection

- Welded or Bolted

- Material

- Galvanized Iron (GI)

- Floor Material

- Galvanized Iron (GI)

- Floor Load

- Tailored as per structural design (typically up to 300 kg/sq.m.)

- Color

- Silver/Metallic

- Use

- Industrial Platforms, Walkways, Trench Covers, Flooring

- Bearing Bar Size

- Range: 20mm x 3mm up to 50mm x 5mm

- Surface Type

- Plain or Serrated

- Maintenance

- Low maintenance

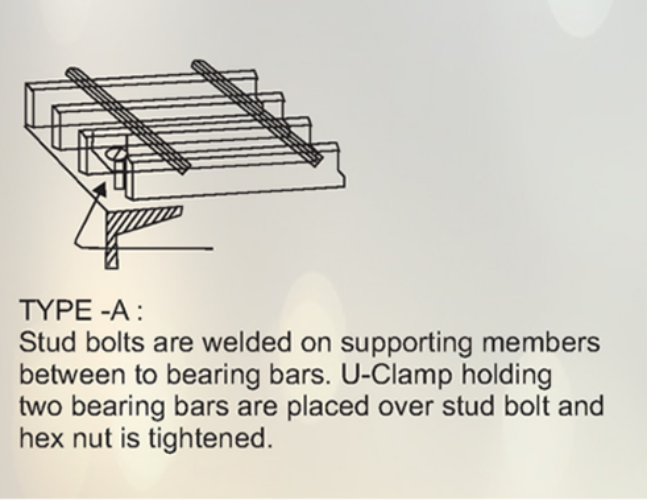

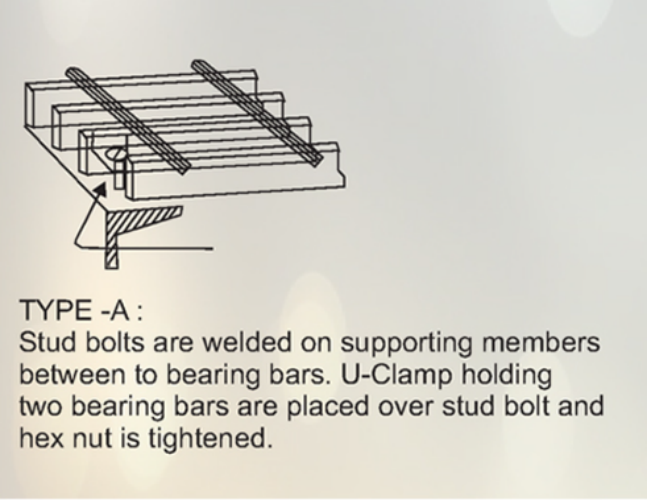

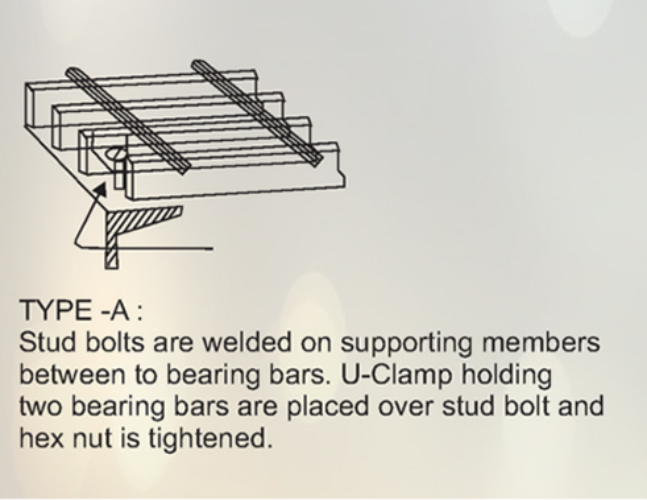

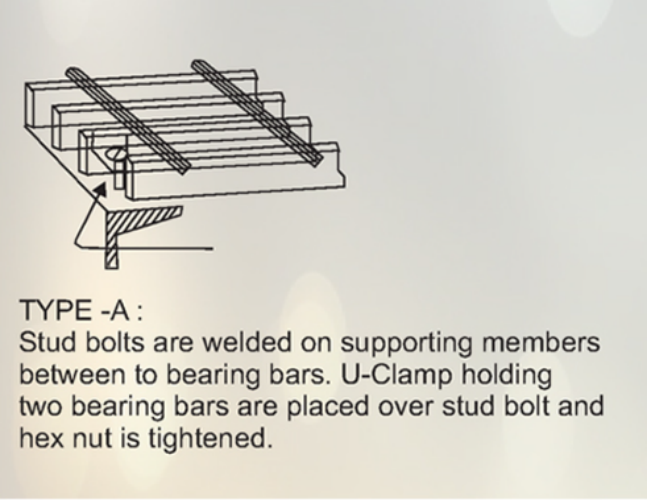

- Installation Method

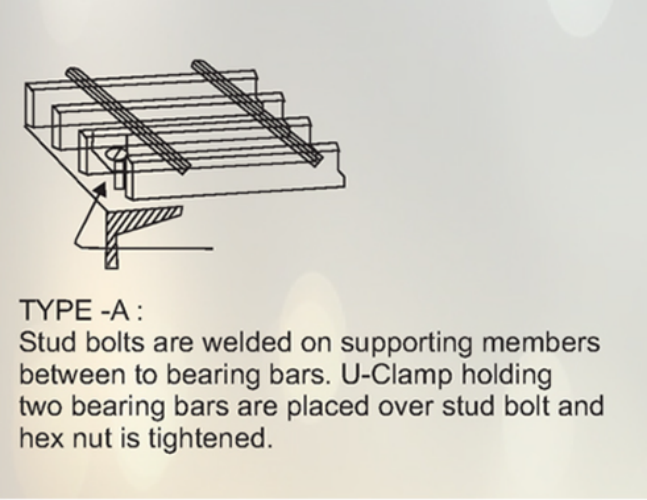

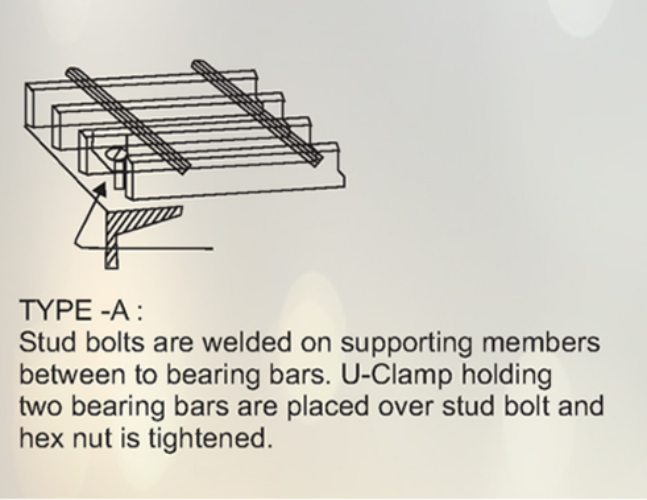

- Welding, Bolting, or Clamping

- Load Capacity

- Varies by specification, up to 5,000 kg/m²

- Packing Type

- Stacked, Wrapped, or as per client requirement

- Cross Bar Pitch

- Typically 50mm or customized

- Application

- Drainage Covers, Catwalks, Stair Treads, Industrial Floors

- Finishing

- Hot Dip Galvanized

- Shape

- Rectangular / Square / Custom shapes available

- Corrosion Resistance

- High (due to GI coating)

- Edge Type

- End Bands and Toe Plates if required

- Bearing Bar Pitch

- Typically 25mm, 30mm or as required

- Mesh Type

- Rectangular Grill

GI Grating Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Domestic Market

- All India

About GI Grating

Construction and features

- Material:Made from mild carbon steel that is coated with a layer of zinc, a process called galvanization.

- Corrosion resistance:The zinc coating protects the steel from rust, making it suitable for wet, outdoor, or chemically aggressive environments.

- Strength and durability:Designed to handle heavy loads and withstand harsh conditions, with a high safety factor.

- Permeability:The open grid structure allows for good water drainage and air circulation, which helps prevent the buildup of snow and ice.

- Safety:The open grid provides a good grip and reduces the risk of slipping.

Common applications

- Industrial flooring and platforms

- Walkways and stair treads

- Drainage covers and grates over vents

- Manhole covers

- Ship decks

- Wet areas and chemical plants

Benefits

- Increased lifespan:Galvanization and the open structure help extend the products life.

- Cost-effective:Despite potentially higher initial costs, its longevity and low maintenance requirements make it cost-effective over time.

- Easy maintenance:The open design makes inspection and cleaning simple.

Versatile Configuration and Design

Our GI Gratings offer flexible design options with customizable bearing bar pitches (typically 25mm or 30mm), cross bar spacing, and mesh patterns. You may choose from plain or serrated surfaces according to traction needs. The gratings can be supplied in rectangular, square, or custom shapes to match any installation requirement.

Superior Corrosion Resistance and Durability

The hot dip galvanizing process grants our GI Grating excellent protection against corrosion, making it suitable for harsh environments. This finish ensures longevity even in industrial and outdoor settings, with a typical service life ranging from 10 to 25 years.

Robust Load Capacity for Industrial Needs

Engineered to support heavy-duty applications, our GI Grating handles loads up to 5,000 kg/m. This robust performance makes it ideal for platforms, trench covers, and flooring in factories, warehouses, and construction sites.

FAQs of GI Grating:

Q: How is GI Grating installed for industrial applications?

A: GI Grating can be installed using welding, bolting, or clamping methods, depending on the structure and application requirements. The choice ensures stability and secure placement on platforms, walkways, and other surfaces.Q: What are the benefits of the hot dip galvanized finish on GI Grating?

A: The hot dip galvanized coating provides exceptional corrosion resistance, prolonging service life and reducing maintenance needs. This finish is ideal for both indoor and outdoor industrial environments.Q: When should plain versus serrated surface GI Grating be used?

A: Plain surfaces are typically used in areas with low slip risks, while serrated surfaces are preferred in environments prone to oil, water, or hazardous conditions, as they offer enhanced traction and safety.Q: Where is GI Grating commonly utilized?

A: GI Grating finds widespread use in drainage covers, catwalks, stair treads, trench covers, industrial floors, and platforms, particularly in factories, plants, and construction projects across various industries.Q: What customization options are available for GI Grating dimensions and shapes?

A: We offer tailored dimensions (commonly 1000mm x 600mm x 25mm or as specified) and various shapes, including rectangular, square, and custom configurations, to meet the exact needs of your project.Q: How is the load capacity determined for GI Grating?

A: Load capacity depends on bar size, pitch, material, and grating thickness, with some configurations supporting up to 5,000 kg/m. Our experts can assist in selecting the optimal design for your structural requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

"We are mainly dealing with bulk quantity order inquiries."

|

MITR MECHANIQUE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry