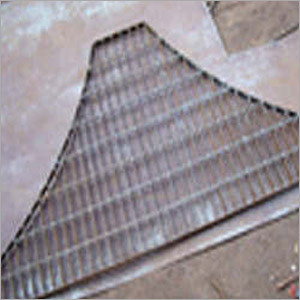

Industrial MS Gratings

Price 85 INR/ Kilograms

Industrial MS Gratings Specification

- Shape

- Rectangular / Square / Custom shapes

- Height

- 25 mm to 100 mm

- Length

- Up to 6000 mm

- Product Type

- Industrial MS Grating

- Material

- Mild Steel (MS)

- Surface Treatment

- Hot dip galvanized / Painted / Plain

- Size

- Customized sizes as per requirement

About Industrial MS Gratings

Industrial MS Gratings

Backed by the rich industry base and experienced personnel, our company has been able to emerge as one of the eminent manufacturers & suppliers of Industrial MS Gratings. We use quality raw materials and modern machines during the development of these gratings. Used in oil and sugar industries, these Industrial MS Gratings are highly appreciated by our clients due to their high strength, easy installation and durability. We stringently check these gratings on quality parameters to offer flawless range.

Versatile Grating Solutions

Our industrial MS gratings provide adaptable options to address various industrial needs, from walkways to heavy-duty flooring. Manufactured using high-quality mild steel and offering numerous customizations, these gratings fulfill unique project specifications efficiently. Choose from surface treatments like hot dip galvanizing, painting, or leave them plain, ensuring optimal performance in different environments.

Durability Through Advanced Treatment

Hot dip galvanization and professional painting processes shield MS gratings from harsh industrial environments and corrosion. These treatments significantly prolong the gratings lifespan, reducing maintenance needs and ensuring safety. Our plain gratings cater to those requiring further customization or wishing to apply specialized surface coatings themselves.

FAQs of Industrial MS Gratings:

Q: How are industrial MS gratings with surface treatment manufactured?

A: Industrial MS gratings are produced using mild steel, cut and fabricated to custom sizes, then treated with either hot dip galvanizing for corrosion resistance, painting for added protection and aesthetics, or left plain for specific user applications.Q: What options are available for the dimensions and shapes of these gratings?

A: We provide gratings in heights ranging from 25 mm to 100 mm and lengths up to 6000 mm. Shapes include rectangular, square, and custom geometries, allowing for complete adaptability to your projects requirements.Q: When should I choose hot dip galvanized, painted, or plain MS gratings?

A: Hot dip galvanized gratings are ideal for environments prone to moisture or corrosion. Painted gratings add both protection and visual appeal, while plain gratings are suitable for controlled environments or for customers planning further customization.Q: Where can these MS gratings be installed and used?

A: These gratings are perfect for industrial platforms, walkways, flooring in factories, warehouses, and other heavy-duty applications across manufacturing, chemical, and utility sectors.Q: What is the process for customizing MS gratings to my project specifications?

A: You can provide your specific requirements for size, shape, and surface treatment. Our team will manufacture the gratings as per your needs and offer installation services to ensure a perfect fit for your site.Q: How do these surface treatments benefit the performance of MS gratings?

A: Surface treatments like hot dip galvanizing and painting protect against rust, wear, and harsh chemicals, significantly enhancing durability, safety, and reducing the frequency of maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Gratings Category

Hot Dip G.I Metal Gratings

Price 105 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Material : Other , Hot Dip Galvanized Iron (G.I)

Shape : Other, Rectangular or customized as per design

Size : Standard or customized as per requirement

Product Type : Hot Dip G.I Metal Gratings

Stainless Steel Grating

Price 350 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Material : Stainless Steel

Shape : Other, Rectangular

Size : Customizable as per requirement

Product Type : Stainless Steel Grating

Industrial Mild Steel Gratings

Price 85 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Material : Other , Mild Steel

Shape : Other, Rectangular / Square

Size : Customizable as per requirement

Product Type : Industrial Mild Steel Gratings

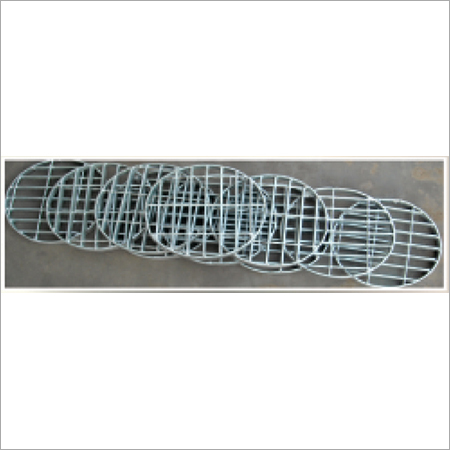

Round Metal Grating

Price 85 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Material : Other

Shape : Round

Size : Varies

Product Type : Grating

|

MITR MECHANIQUE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry